Rotary airlocks play a crucial role in pneumatic conveyance systems, acting as the linchpin in the seamless flow of materials. If you’re curious about these essential components, we’re here to provide the knowledge you need.

Understanding Rotary Airlocks:

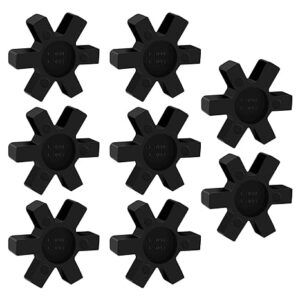

Rotary airlocks, also known as rotary valves or rotary feeders, are precision-engineered devices designed to control the flow of bulk materials between two different environments with varying levels of pressure or temperature. They are the gatekeepers that maintain system integrity and efficiency in pneumatic conveying.

How Do They Work?

Rotary airlocks function by rotating at a controlled speed, creating a seal between different process stages. This rotation allows a precise volume of material to pass through while preventing air or gas leakage, ensuring a consistent flow of materials.

Types of Rotary Airlocks:

There’s no one-size-fits-all when it comes to rotary airlocks. They come in various configurations to suit specific material handling needs, including standard-duty and heavy-duty options, and are available in various materials such as stainless steel or cast iron.

Applications Across Industries:

Rotary airlocks find their place in an array of industries, from food processing and agriculture to pharmaceuticals and chemical manufacturing. They facilitate the efficient transfer of materials, enhancing productivity and reducing waste.

At Progressive Products, we’re committed to providing the education and high-quality rotary airlocks you need for your pneumatic conveyance systems. Join us on a journey of understanding these vital components and discover how they can elevate your material handling processes.

Reviews

There are no reviews yet.